Transform Your BOM Operations

Agriculture

Engineering

Cables

Chemical

Electrical

Steel & Iron

Plastics

Real Estate

What is BOM ?

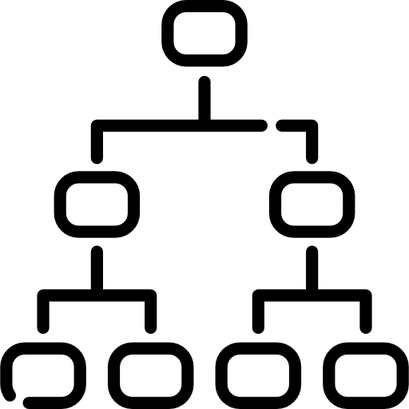

A Bill of Materials (BOM) is at the heart of the Manufacturing system and the most important document that will help to create other document types like Work Orders and Job Cards. ERPNext supports multi-level BOM.

The BOM is a list of all materials (either bought or made) and operations that go into manufacturing a finished product or sub-assembly. In ERPNext, each item (sub-assembly) could have its own BOM hence forming a tree of Items with multiple levels.

- A Bill of Materials is a list of items and sub-assemblies with quantities required to manufacture an Item.

- A BOM may also contain the manufacturing operations required to manufacture the Item.

Benefits of BOM

A well-structured Bill of Materials (BOM) in ERPNext ensures seamless manufacturing operations by providing accuracy, transparency, and efficiency across the production cycle. Here are the key benefits:

- Improved Production Efficiency: Clearly defines all raw materials and sub-assemblies required.

- Reduced Manufacturing Errors: Minimizes mistakes through accurate documentation.

- Better Cost Control: Tracks material, labor, and overhead costs precisely.

- Effective Inventory Management: Prevents shortages and avoids overstocking.

- Faster Decision-Making: Provides real-time visibility into material availability.

- Team Collaboration: Aligns design, procurement, and production teams seamlessly.

- Enhanced Product Quality: Standardizes processes for consistent results.

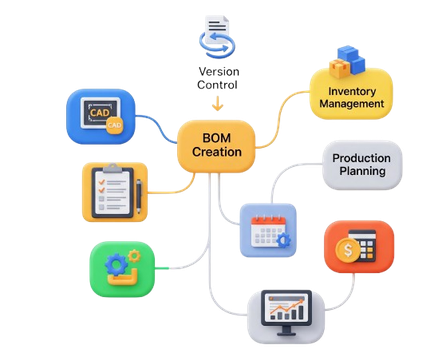

A Glimpse of BOM Operation Features

Multi-Level BOMs

Create and manage single-level or nested multi-level BOMs for complex products with sub-assemblies.

Operation Management

Define and link manufacturing operations with workstations, including time and cost tracking.

Accurate Costing

Get real-time cost estimates by combining material, labor, and overhead costs within each BOM.

Version Control

Maintain multiple versions of BOMs, track revisions, and ensure only the latest version is used in production.

Material Tracking

Monitor raw materials, substitute items, and scrap management directly from the BOM.

Routing & Scheduling

Define operation sequences and schedule them efficiently to optimize production timelines.

Integration with Work Orders

Seamlessly convert BOMs into Work Orders for hassle-free production planning.

Reports & Analytics

Generate detailed BOM cost reports, variance analysis, and performance insights for smarter decision-making.