Optimize Your Production with ERPNext Manufacturing

Ditch inefficient processes and siloed systems. Plan, track, and optimize manufacturing operations seamlessly for better efficiency, reduced costs, and faster delivery.

One Module to Master Your Manufacturing Workflow

ERPNext Manufacturing integrates production planning, inventory, and quality control into a unified platform, empowering you to build products smarter and scale effortlessly.

How ERPNext Manufacturing Powers Your Operations

1. Plan Production

Create detailed production plans based on sales orders, forecasts, and inventory levels for optimal resource allocation.

2. Define BOMs

Build multi-level Bill of Materials with costs, operations, and routing to ensure accurate material and time estimates.

3. Execute Work Orders

Generate work orders, track progress in real-time, and manage shop floor activities with job cards and timesheets.

4. Ensure Quality

Perform inspections at every stage, maintain compliance, and reduce defects with integrated quality management.

Comprehensive Manufacturing Features

🛠️ Production Planning & Scheduling

Forecast demand, schedule operations, and balance workloads across machines and teams for on-time delivery.

📋 Bill of Materials (BOM)

Create detailed, version-controlled BOMs with explosion/implosion views, costing, and variant support.

🏭 Work Orders & Job Cards

Automate work order creation from sales, track operations, and capture time and materials on the shop floor.

🔍 Quality Control & Inspections

Set up quality procedures, perform in-process and final inspections, and generate compliance reports.

📦 Inventory & Warehouse Management

Integrate with stock module for real-time tracking of raw materials, WIP, and finished goods with serial/batch support.

🤝 Subcontracting Management

Outsource processes seamlessly with purchase orders, material transfers, and cost tracking for subcontractors.

📈 Capacity & Resource Planning

Plan machine and labor capacity, simulate scenarios, and optimize utilization to avoid bottlenecks.

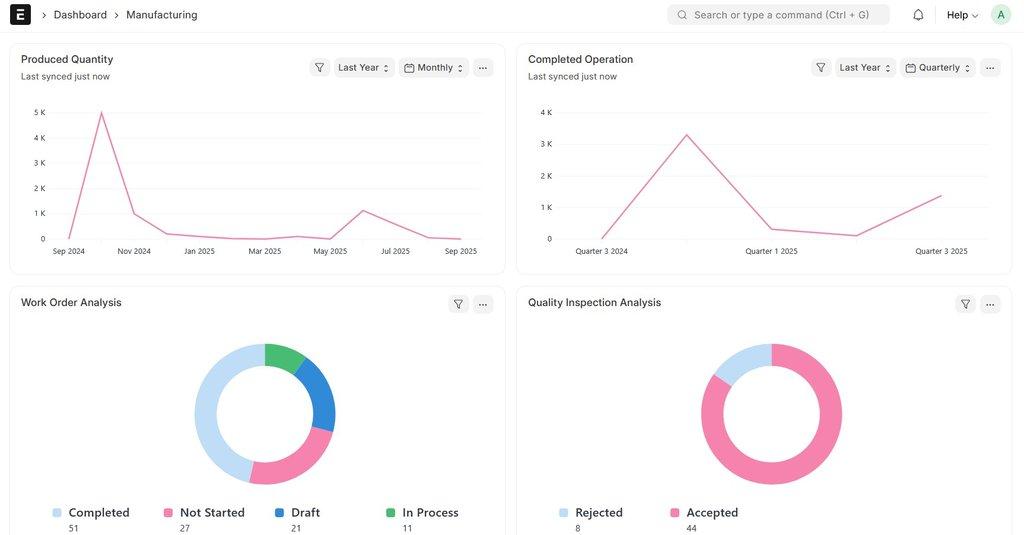

📊 Analytics & Reporting

Get insights with production analytics, downtime reports, efficiency metrics, and customizable dashboards.

Why Manufacturers Rely on ERPNext

Empowering production teams in 150+ countries to deliver quality products efficiently and profitably.

40%

Increase in production efficiency

30%

Reduction in inventory costs

25%

Faster time-to-market

Ready to Revolutionize Your Manufacturing?

Schedule a tailored demo to discover how ERPNext can boost your production capabilities and drive growth.

Book a Free Demo